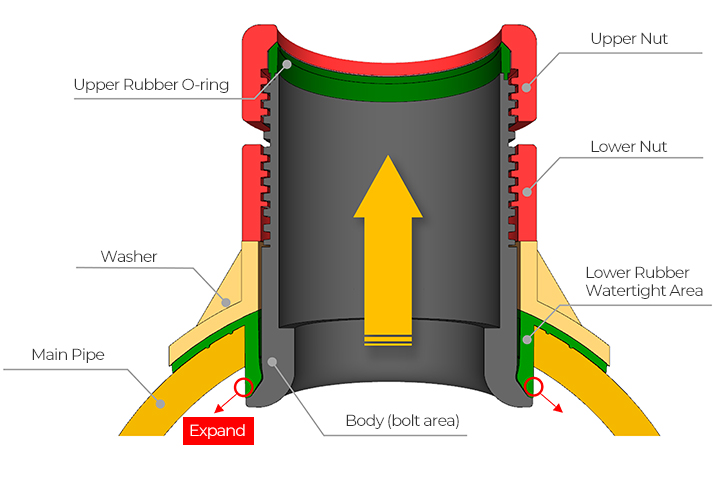

LS Branch Sphere is a patented product that adopts an internal watertight structure with an inclined plane. It can be applied to all types of main pipes with diverse specifications.

It can be easily, yet perfectly, installed to connect the main sewer pipe and its branching pipes - when the lower nut is tightened after inserting the LS branch sphere into the hole on the main pipe, the body rises and the lower packing affixes itself as it expands inside the main pipe alongside the inclined plane in the lower part of the body. It prevents soil pollution from leakage of sewage and overloading by seepage of underground water and rainwater.

It can be applied to rain and sewage pipes, pipes for urban and apartment building constructions, and pipes for various types of housing site construction.

It adopts a non-melting, non-gluing tightening method, which makes it easy to be installed and saves a significant amount of construction time. It is a patented product featuring an internal watertight structure with an inclined plane. It has excellent watertight performance and can be applied to various types of pipes, such as PE pipe, GRP Pipe, DC pipe, PVC pipe, PCF pipe, hume pipe, etc.

It is made of high-alluvial ABS, which makes it very durable, impact-resistant and corrosion-resistant. The perforator and tightener are available for easy installation. With KUKIL INNTOT’s LS branch sphere; you do not need to excavate the areas below and around the main pipe to install the branch sphere.

KUKIL INNTOT’s LS branch sphere is patented, and is of excellent quality - it acquired various certifications, such as the excellent government procurement product certificate, performance certificates, and the industry standard certificates.

When inserting the LS branch sphere into the perforated pipe and tightening the lower nut, the body rises thereby expanding the bottom part of the lower rubber packing inside the pipe, adhering to the perforated side to create and maintain water tightness, as it expands alongside the inclined plane on the body.

Perfect water tightness on the perforated side of the pipe can be created by the expanded and pressurized lower rubber packing. As the washer is compressed, the wing on the lower rubber packing additionally compresses the outside of the pipe, creating a secondary watertight effect.

When the main pipe and the LS branch sphere are joined by the above process, the branch pipe is inserted into the LS branch sphere and the upper nut is tightened, the upper O-ring strongly compresses the outside of the branch pipe as the upper nut is compressed, thus fixing the branch pipe and maintaining water tightness.