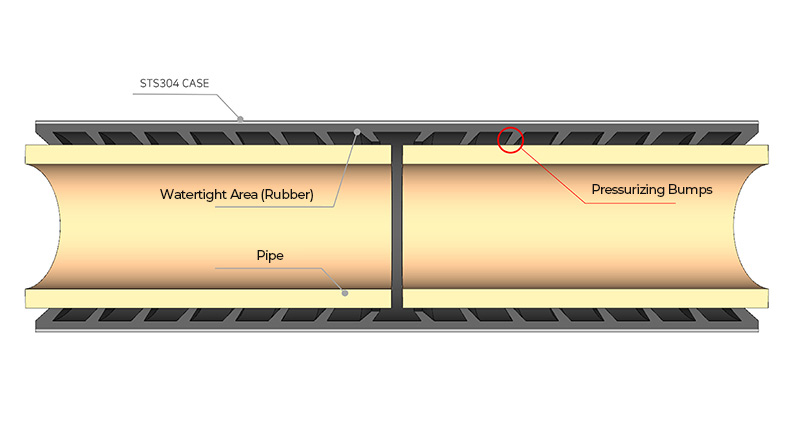

The solid-type round pipe support connector consists of the tightening part (casting and U-angle) made of STS304, and the rubber (watertight area) composed of NBR and soft PVC and NBR. It utilizes non-melting sewer pipe connecting technology that tightens and connects the PE sewer pipe with the bar made of ABS and T-shaped bolts by a simple and easy bolting method.

U-shaped angles and t-bolts were applied to this connector so that it can apply the maximum degree of pulling force even to the lower part of the pipe. It adopts a totally different mechanism compared with the conventional melting type connectors.

This connector can be used to connect sewer pipes used for wastewater and rainwater, such as double-walled PE pipes, multiple-walled pipes, filled-wall pipes, and glass fiber complex pipes. It is suitable for:

Adopts the non-melting tightening method that requires no equipment for melting - making it easy to install.

The U-shaped angle makes it more durable than the existing angles.

T-shaped bolt and separating bars can be handled with one tool.

Its case and angle are made of STS304 (stainless steel), which makes it highly durable, erosion resistant and wear-resistant.

A special synthetic rubber with excellent durability is used to absorb shocks and vibrations.

It can be installed in the rain and in wetland areas, and it can be disassembled and reinstalled when the pipe is clogged.

Pressurizing bumps are closely spaced inside the watertight area in the shape of sealed bands pointing at the area where the pipes are connected, thus preventing water leakage in steps.