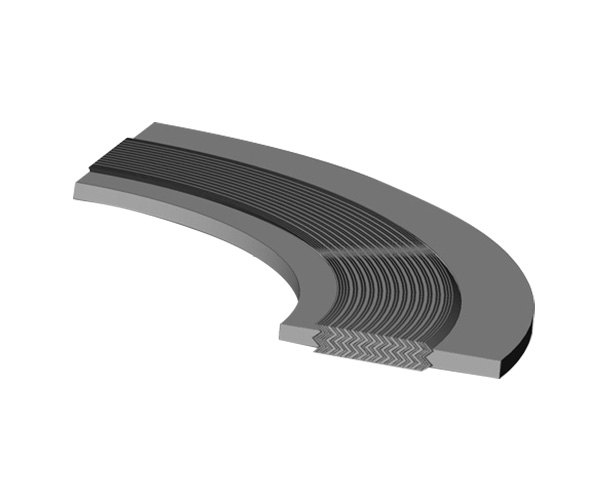

Spiral Wound Gasket - OSI

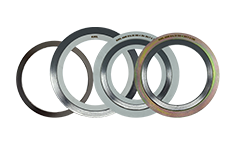

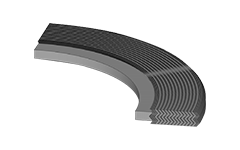

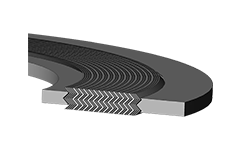

The OSI type gasket is manufactured by attaching metallic rings made of various metals in the inner and outer walls of the basic-type gasket. The inner wall does not deform even when it is over-compressed by the inner ring, and the outer ring can be easily assembled. It has an improved pressure resistance and the highest reliability.

OSI is a typical type of spiral wound gasket that can be applied in environments of extreme cold, high temperature, and high pressure. It is used for many different purposes, including power-generation plants, shipyards, refineries, petrochemical plants, and other plants.

-

Product Features

- Prevent deformation of gasket body

- Stable center fitment and easy assembly

- Various hoops and non-metallic fillers can be applied depending on the use environment

- Easy Installation and Removal

- Stable sealing performance

-

Product Specifications

- Working pressure : ASME CLASS 2500#

- Working temperature : -240℃ ~ 1000℃

- Manufactured dimensions : 1/2“ ~ 5000Ø

- Gasket Thickness : 3.2mm / 4.5mm / 6.4mm / 7.2mm

- Gasket Factor : m - 3

y - 10,000psi

-

Applicable Lines

- A variety of Flange, including Raised and RTJ, etc

- Valves and pumps

- Ultra-low temperature pipe laying

- Pressure container

- Plant Facilities

- Shipbuilding and refinery industries

- Power plant and petrochemical industry

-

Data